Our solution

The AQ solution is based on close of a decade of development and prototyping. The system has been designed, developed and prototyped as a general industrial aerator, able to reliably function under various difficult operating conditions. As-is, the system can be implemented in both on-land and off-shore aquaculture applications. The solution is based on a unique approach to provide effective aeration, that makes it superior to existing solutions.

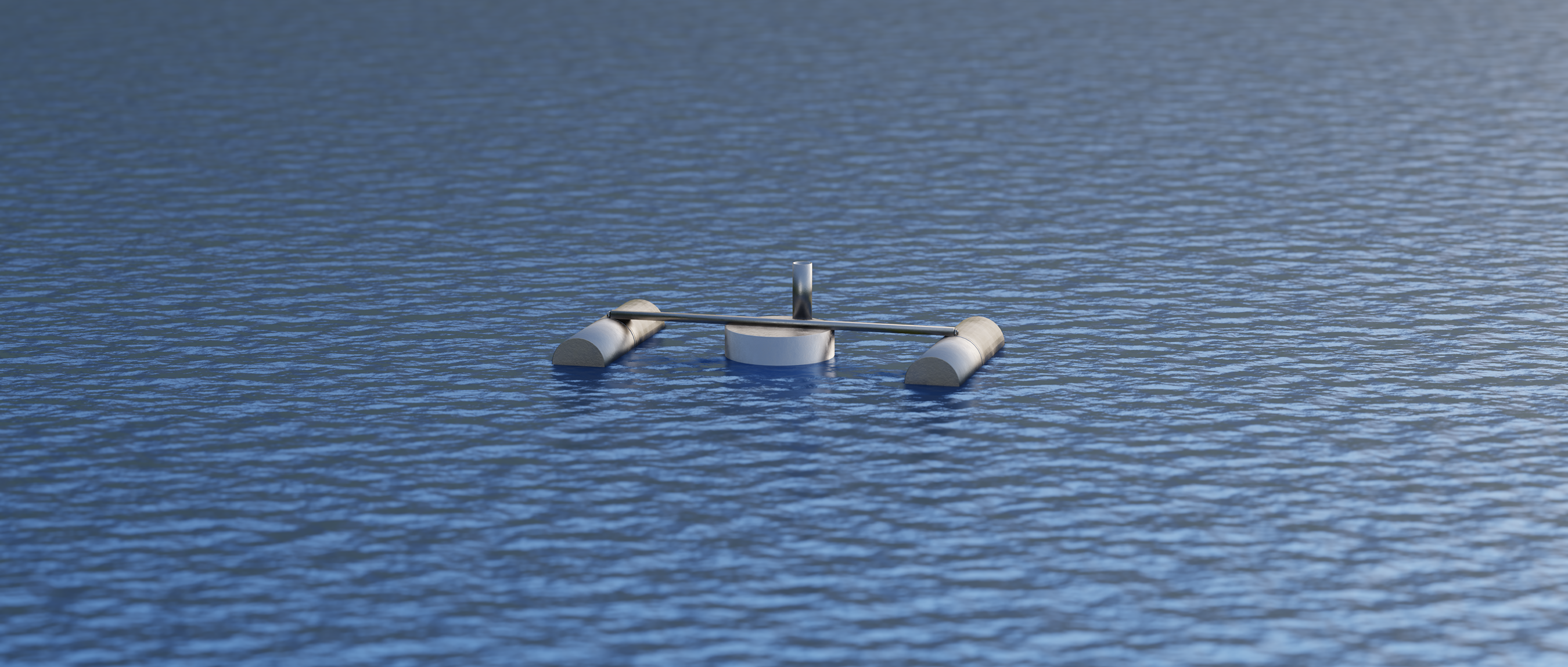

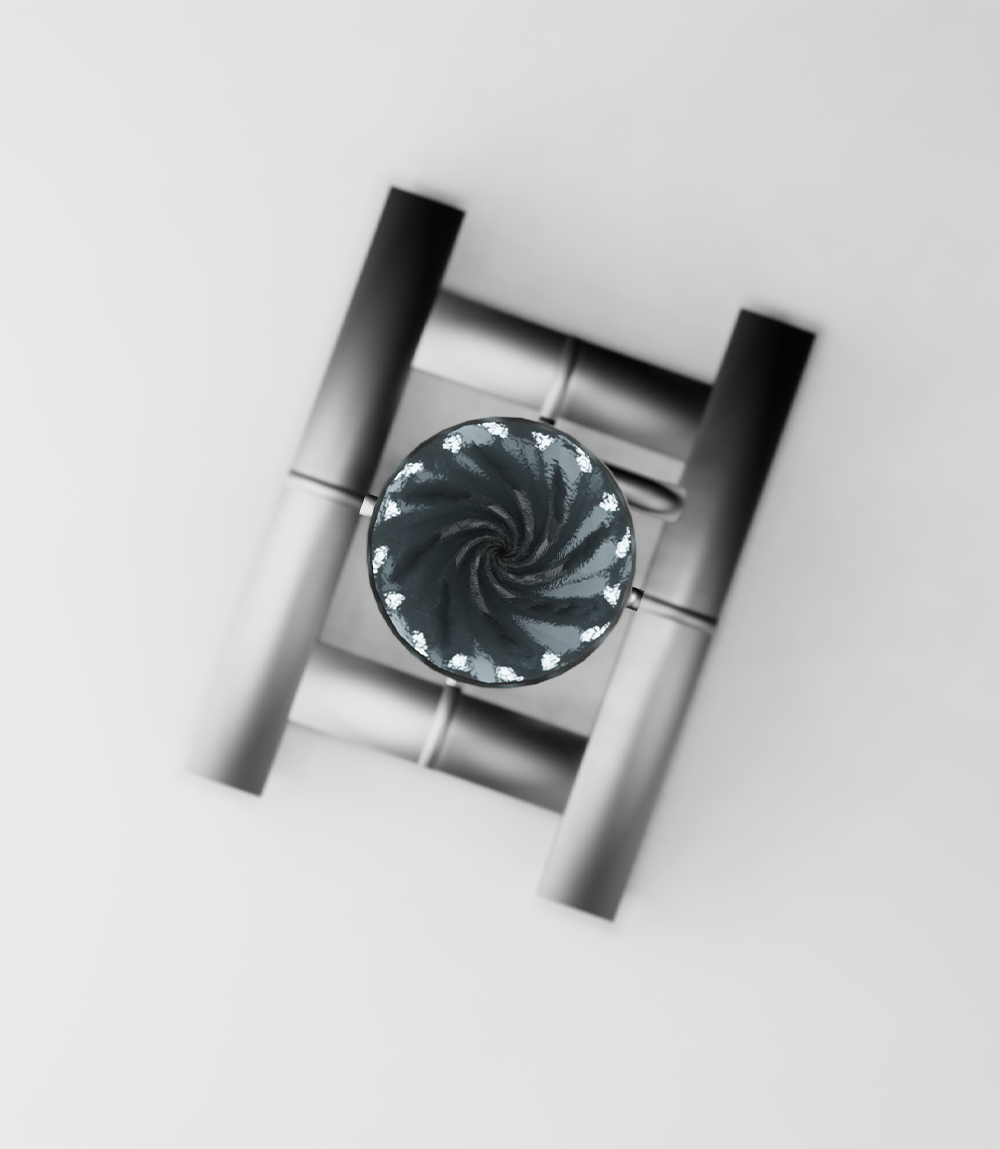

In contrast to present commercial solutions for aquaculture, that are based on either mechanical stirring or distribution of compressed air, the AQ both stirs and oxygenates water at the same time. The system is based on a floating platform with a submerged impeller that sucks air through hoses that can be repositioned around the platform. The pump-driven impeller creates large vortexes with a significant proportion of micro bubbles. In relation to average air bubbles (2mm >), micro bubbles (0,02mm <) stay submerged in water for extended periods of time and travel further and wider than average bubbles. They thus oxygenate the water more efficiently than present technologies. The Aquagyro system consistently delivers over 7 kg O2/kWh.

To put this into perspective, the present average aerator efficiency under standard measurement conditions is (Svenskt Vatten, 2019):

Surface blowing compressed air: 0,9 – 2,1 kg O2/kWh.

Jet blowing compressed air: 1,1 – 2,2 kg O2/kWh.

Coarse bubble blowing compressed air: 0,6 – 2,2 kg O2/kWh.

Fine bubble blowing compressed air: 2,6 – 7,1 kg O2/kWh.

Combined stirrer/aerator stirring/blowing compressed air: 1,2 – 2,1 kg O2/kWh. The reduced energy consumption means that the AQ significantly reduces operating costs for the user:

The Aquagyro system is the result of decades of experience of aeration development and prototyping.

The results

Aquagyro reduces energy consumption by up to 70% in relation to present technologies, and significantly reduces evaporation water loss. The system is scalable, allowing for multi-unit installation that creates significant redundancy and energy savings in comparison to present solutions.

Extensive true testing

The Aquagyro system builds on decades of aerator design experience. One of the earliest prototypes has been operating for over a decade in Northern Sweden with minimal maintenance.